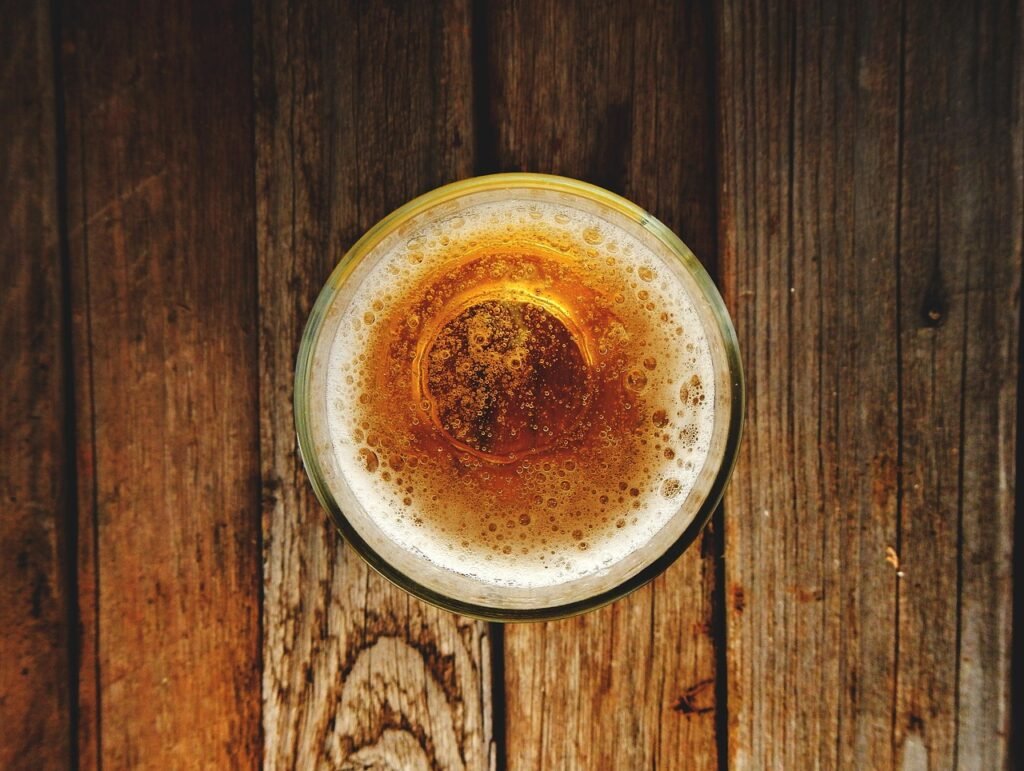

Starting a beer business, whether on a craft or industrial scale, goes far beyond understanding the technical flow of the beer processing and bottling process. While the fundamentals of brewing, filtration, filling, and packaging may appear straightforward in a flow chart, real-world operations introduce layers of complexity that every brewery must be prepared to navigate.

One of the first challenges is capital investment: equipment for brewing, bottling, labeling, and quality control requires significant upfront costs, and scaling production later can mean reinvesting in larger or more automated systems. Closely tied to this is space management. Breweries often underestimate how much room is needed not just for tanks and bottling lines, but also for storage, refrigeration, and future expansion.

Another critical struggle lies in quality consistency. From craft brewers experimenting with new recipes to industrial producers managing large-volume runs, ensuring that every bottle meets the same flavor, carbonation, and shelf-stability standards is a constant effort. This requires strict attention to sanitation, reliable filtration methods, and robust monitoring systems. On top of that, regulatory compliance is an ongoing consideration.

Depending on your region, breweries must adhere to food safety standards, labeling requirements, and alcohol distribution laws, each of which can influence how you set up your beer processing and bottling process.

Finally, market positioning should not be overlooked. Craft breweries face the challenge of standing out in a crowded niche with unique branding and limited production capacity, while industrial breweries must balance efficiency with sustainability and public perception. Packaging design, choice of materials, and even bottling speed can all affect how a product is received by distributors and consumers. By being aware of these struggles early, brewers can make informed decisions, choose the right suppliers, and set a foundation for sustainable growth in a highly competitive industry.